INSERTION OF RECOMBINANT DNA INTO THE HOST CELL/ORGANISM

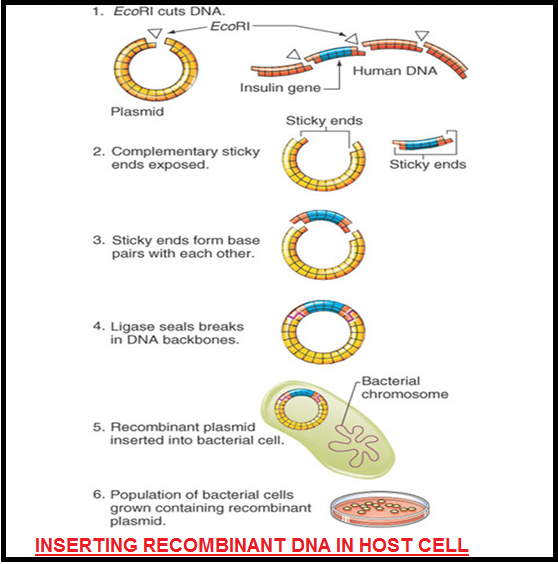

● There are several methods of `color{Violet}"introducing the ligated DNA"` into recipient cells.

● Recipient cells after making them `color{Violet}"competent"` to receive, `color{Violet}"take up DNA"` present in its surrounding.

● So, if a recombinant DNA bearing `color{Violet}"gene for resistance"` to an antibiotic (e.g., ampicillin) is transferred into `color{Violet}"E. coli cells"`, the host cells become transformed into `color{Violet}"ampicillin-resistant cells"`.

● If we spread the transformed cells on `color{Violet}"agar plates"` containing `color{Violet}"ampicillin"`, only `color{Violet}"transformants will grow,"` untransformed recipient cells will die.

● Since, due to `color{Violet}"ampicillin resistance gene"`, one is able to `color{Violet}"select a transformed cell"` in the presence of ampicillin.

● The `color{Violet}"ampicillin resistance gene"` in this case is called a `color{Violet}"selectable marker"`.

● Recipient cells after making them `color{Violet}"competent"` to receive, `color{Violet}"take up DNA"` present in its surrounding.

● So, if a recombinant DNA bearing `color{Violet}"gene for resistance"` to an antibiotic (e.g., ampicillin) is transferred into `color{Violet}"E. coli cells"`, the host cells become transformed into `color{Violet}"ampicillin-resistant cells"`.

● If we spread the transformed cells on `color{Violet}"agar plates"` containing `color{Violet}"ampicillin"`, only `color{Violet}"transformants will grow,"` untransformed recipient cells will die.

● Since, due to `color{Violet}"ampicillin resistance gene"`, one is able to `color{Violet}"select a transformed cell"` in the presence of ampicillin.

● The `color{Violet}"ampicillin resistance gene"` in this case is called a `color{Violet}"selectable marker"`.